What is BIM?

BIM stands for Building Information Modeling, and the terms behind the acronym already indicate that the origins of the methodology lie in building design – more specifically in building construction. BIM was also developed as a holistic planning methodology, which is why it's partly synonymous use as a purely digital planning tool does not fully reflect the underlying concept.

The core element of the BIM methodology is the implementation of a central information carrier, a so-called single source of truth, within the planning process. Interface-free planning, visualization and coordination of all relevant planning information combine the three most important domains that were previously developed and maintained in separate planning environments.

The successful execution of initial industrial construction projects based on BIM, the increasing standardization for relevant applications, and the catalytic effect of the mandatory introduction of BIM for public construction projects have established BIM as the leading planning methodology in the construction industry.

What role does BIM play in factory planning?

The successful application of BIM in construction soon raised the justified question of why this new role model should not also be applied in directly adjacent disciplines such as factory planning – especially since the interpretation of BIM as a holistic methodology inherently implies such a cross-disciplinary approach.

As a result, foundational work was first carried out in academic research before the considerable potential was demonstrated through initial industrial applications.

The fact that planning is typically carried out in 3D makes (intermediate) results visually accessible at any time. This is an important benefit, but not the most important one achieved through the use of BIM in factory planning.

From a factory planning perspective, the ‘game changer’ lies in the fact that geometric and alphanumeric data and information are managed within a single planning environment. The labor-intensive and significantly more error-prone consolidation via often custom-built interfaces between CAD programs, Excel spreadsheets and other external sources becomes obsolete. This fundamental concept simplifies both planning within the factory planning discipline itself and cross-disciplinary collaboration with other trades.

What benefits arise from using BIM in factory planning?

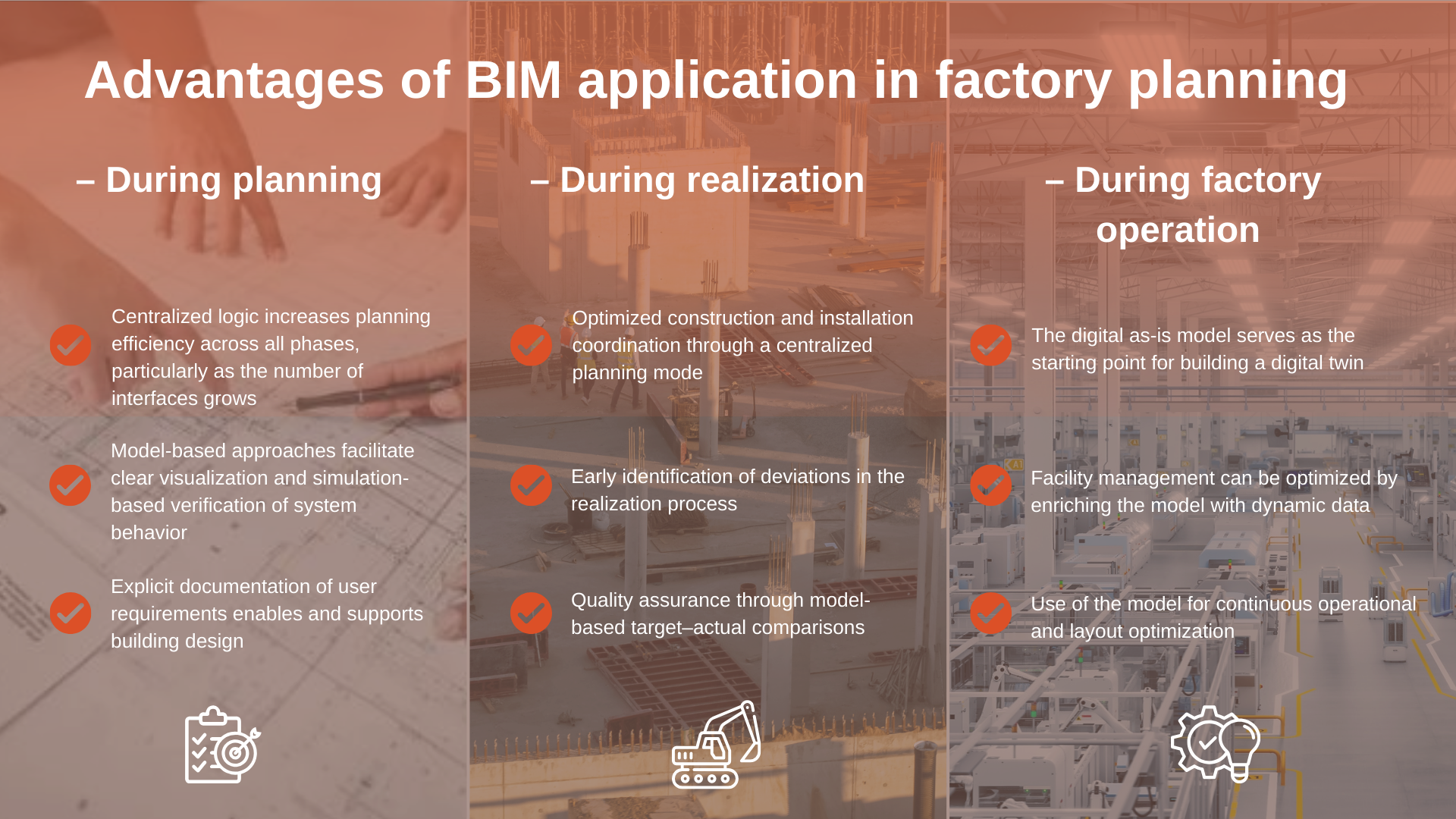

The use of BIM in factory planning optimizes planning, enables more efficient execution, and lays the foundation for a digital factory operation.

Benefits during factory planning

Centralized logic increases planning efficiency across all phases, especially as the number of interfaces grows

Clear visualization of (intermediate) results and implications of changes (e.g. layout adjustments) across all planning phases

Model-based planning facilitates verification of system behavior through simulation

Early enablement of building design based on clearly defined and traceable user requirements

Preventive avoidance of collisions between equipment and building infrastructure

Benefits during realization

Optimized construction and installation coordination through a centralized planning model

Early identification of deviations in the realization process

Quality assurance through model-based target-actual comparisons

Benefits for digital factory operation

A digital as-is model serves as the basis for building a digital twin

Facility management can be optimized by enriching the model with dynamic data

Use of the model for continuous operational and layout optimization

Are there currently still challenges in application?

Standardization

The ‘time advantage’ in property planning means that those involved have already been able to agree on a higher level of standardization than is currently the case in factory planning.

Level of detail and storage capacity

Depending on the specific factory characteristics, initialized model environments can require substantial data capacity. Ideally, the appropriate level of detail should therefore be defined at an early stage to ensure effective and goal-oriented use of the model.

Change Management

It is also essential that not only planners interact with the methodology, but that factory operators develop an understanding of BIM and receive training in the relevant tools. This step is crucial in order to anchor BIM-based planning within the organization as a starting point for digital factory operation.

A brief conclusion

Overall, the advantages clearly outweigh the remaining challenges. BIM will continue to accelerate the digitalization of industrial factory planning projects and will generate significant benefits in terms of quality, cost and efficiency.

About the Authors

Contact

Contact

Simon Vehof

Manager Business Development

Matthias Göke

Managing Partner - Factory Planning